Murugappa Morgan

Non-Ferrous Metals

Working with you to achieve reduced emissions through innovation and energy efficient linings

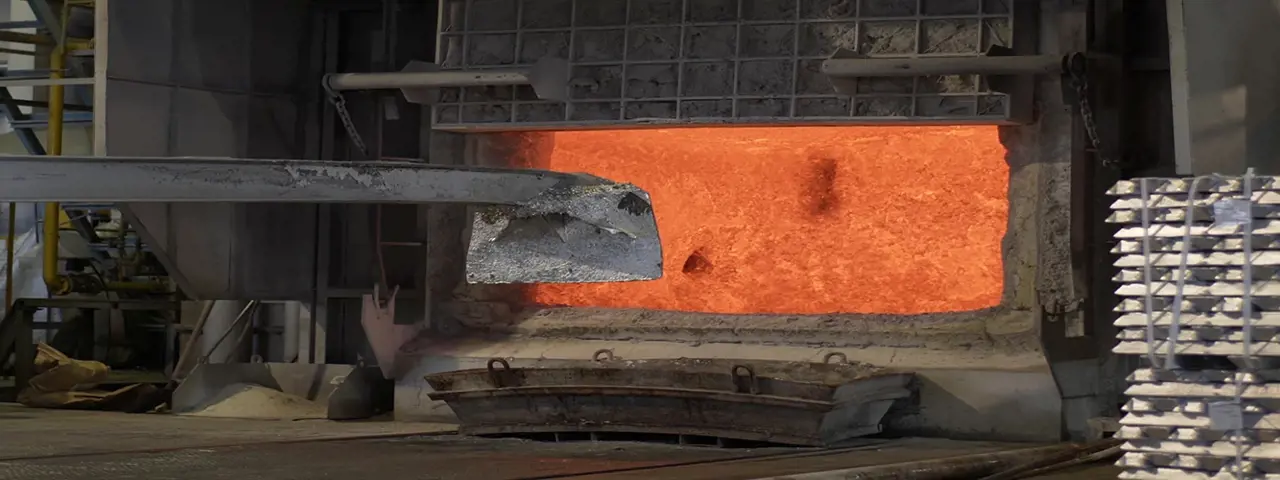

Non-Ferrous Metals manufacturing presents some of the world’s most challenging operational environments, for equipment and people. Our advanced solutions in refractory, fibre, and microporous are chosen to fulfil critical applications in furnaces and molten transfer applications.

Partnering with industry leaders, we have developed technologies and systems for furnace linings, ladles and crucibles that will achieve energy savings, increase capacity, enhance the lifecycle performance of your equipment and improve safety for your people.

Application Solutions

Copper

Launders: To prevent solidification, the launders are covered with our Superwool Boards and WDS Microporours Insulation to prevent the loss of heat. Converters: Our Water Resistant Superwool Plus Boards and AZS Boards are used as an effective backup lining in the converters. Additionally, the retention of the size and shape of the back-up boards without disintegrating, provides better insulation and energy efficiency. Anode Furnace: AZS boards are used as backup in the Anode Furnace. This reduces the overall lining thickness and the weight of the equipment making it more energy efficient.

Zinc

Vacuum Formed shapes and boards are used in the process of zinc extraction. Tap out cones are used as stoppers while tapping the melt for forming and to control the flow of the molten metal for further processes. Superwool Boards serve as an excellent backup in the holding furnaces of zinc melting operations.

Gold

Superwool Plus Boards have proven their superior insulation efficiencies in furnaces used for the Gold melting process in the jewelry industry.

Superwool® fibres, our market leading low biopersistent high-temperature thermal insulating solutions are favoured by the aluminium industry for its excellent thermal performance and resistance to aluminium wetting.

Superwool LBP Fibres can be found in our Boards and Shapes that are flexible and rigid to support applications such as sleeves, cones, ladles, and launders.

Our complete line of Coatings and Mastics, like our Superwool Sealcoat™ HT offer additional lining protection to the furnace and door and in maintenance conditions where online and offline hot-spot solutions are required.

WDS® Ultra™ and LambdaFlex® Super Microporous products are ideal for insulation of the melting furnace and when the need to increase volume in transfer or poring ladles is required.

Refractory Monolithics like Morflo®, Hicast™, Alcast™, Higun™, Plascast™ and Plasgun™ have proven performance for areas within the manufacturing environment. With features like superb resistant to mechanical impact and thermal shock.

These thermally superior material properties allow us to engineer effective and reliable thermal management systems that maintain optimal temperature distribution inside the furnace, ladle, crucible or inside the casting process for an improved life of the applications.